PVC Floor Tile Moulds

PVC Floor Tile Moulds Specification

- Cavity

- Single / Multiple (as per requirement)

- Molding Material

- PVC (Polyvinyl Chloride)

- Mold Base

- P20 Steel

- Shaping Mode

- Injection Mould

- Material

- High Quality Steel

- Tolerance

- 0.01 mm

- Mould Weight

- Approx. 50150 kg (Varies by design)

- Mould Life

- 300,000500,000 shots

PVC Floor Tile Moulds Trade Information

- Minimum Order Quantity

- 50 Pieces

- Average Load Time

- 3060 seconds

- Supply Ability

- 10000 Pieces Per Week

- Delivery Time

- 2-5 Days

About PVC Floor Tile Moulds

Floor Tile PVC Moulds

With the able assistance of our team of professionals, we are engaged in offering a wide range of Floor Tile PVC Moulds. These moulds are a perfect solution for external flooring in heavy traffic areas, which do not wear out easily.These products are designed in conformity with the international standards using supreme class raw material and advanced technology. Our offered range is appreciated for its rugged construction, excellent finish and durability. The offered range is in huge demand due to its superior quality features. These Floor Tile PVC Moulds are tested by our team of experts to ensure their superior consistent quality standards.

Versatile Surface Finishes

Our PVC Floor Tile Moulds can be tailored for either glossy or matte finishes, adapting to various aesthetic requirements. The customizable surface ensures your produced tiles match current design trends and satisfy diverse customer preferences.

Precision and Consistency

Each mould is meticulously machined to maintain a tight tolerance of 0.01 mm, guaranteeing each tiles dimensions are accurate and consistent. The use of high-quality steel extends mould life to approximately 300,000500,000 shots, making them ideal for large-scale production.

Customizable Solutions

Whether you need standard 300 mm x 300 mm tiles or unique sizes, our 2D and 3D CAD-supported design process allows for complete customization. Choose from single or multiple cavities and specify other preferences to meet your specific production needs.

FAQs of PVC Floor Tile Moulds:

Q: How are PVC Floor Tile Moulds customized for specific applications?

A: The moulds can be customized in size, surface finish (glossy or matte), cavity configuration, and runner system (hot or cold). Our design team works with 2D and 3D CAD files to meet your particular requirements.Q: What is the typical process for using these moulds in tile production?

A: The mould is installed in a PVC injection moulding machine. PVC material is heated and injected into the mould cavity, where it takes the desired shape. After cooling, the finished tile is ejected, ready for further processing or installation.Q: When should periodic maintenance be performed on the moulds?

A: Regular maintenance, such as cleaning, should be conducted after several production cycles or as recommended. This helps maintain surface quality, minimizes downtime, and significantly prolongs mould life.Q: Where are these PVC Tile Moulds typically utilized?

A: These moulds are predominantly used by manufacturers, exporters, and service providers engaged in PVC floor tile production. Facilities using PVC injection moulding machines will find these moulds particularly suited to their needs.Q: What are the benefits of using P20 steel for the mould base?

A: P20 steel provides excellent toughness and durability, supporting extended use up to 500,000 shots. This steel type is also compatible with precision machining, ensuring accurate tile replication and lower long-term maintenance costs.Q: How does the runner system affect the moulding process?

A: The choice between cold and hot runner systems optimizes material flow, cycle time, and product finish. Hot runners are suitable for minimizing waste, whereas cold runners can be cost-effective for certain applications.Q: What advantages do these moulds offer to tile manufacturers?

A: Manufacturers benefit from high accuracy, customizable features, a long service life, and minimal maintenance needs, allowing for reliable large-scale production and adaptation to rapidly changing market demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Floor Tiles Moulds Category

Multicolor PVC Moulds For Floor Tiles

Price Range 100.00 - 250.00 INR

Minimum Order Quantity : 50 Pieces

Material : Other, Multicolor PVC

Mould Life : 80,000 100,000 cycles

Life Span : 57 years (with proper care)

Mould Weight : 2.53.5 kg (varies by design)

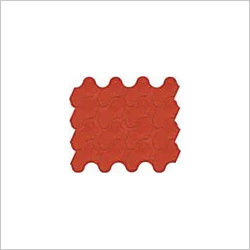

Red PVC Moulds For Floor Tiles

Price Range 100.00 - 250.00 INR

Minimum Order Quantity : 50 Pieces

Material : Other, Polyvinyl Chloride (PVC)

Mould Life : 50,000 80,000 cycles

Life Span : Up to 5 years with proper maintenance

Mould Weight : 2.5 4 kg (approx.)

Designer PVC Moulds For Floor Tiles

Price Range 100.00 - 250.00 INR

Minimum Order Quantity : 50 Pieces

Material : Other, PVC (Polyvinyl Chloride)

Mould Life : Up to 80,000 cycles

Life Span : 58 years

Mould Weight : 2.5 to 6 kg

Home PVC Moulds For Floor Tiles

Price Range 100.00 - 250.00 INR

Minimum Order Quantity : 50 Pieces

Material : Other, Premium Quality PVC

Mould Life : Up to 100,000 cycles

Life Span : Approx. 23 years with standard use

Mould Weight : 1.5 kg 3.0 kg (varies by pattern)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS